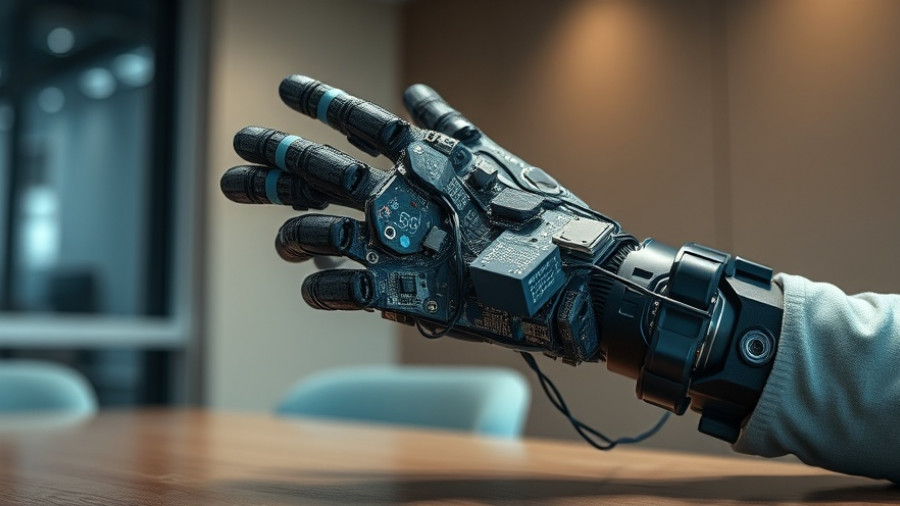

Revolutionizing Safety: The Ergonomics-Driven Tactile Sensing Glove

In today’s increasingly hands-on industries, the importance of ergonomics cannot be overstated. As businesses strive to minimize workplace injuries, the need for innovation in personal protective equipment (PPE) becomes urgent. Enter the Tactile Sensing Glove—an ergonomically designed wearable device engineered to improve safety and efficiency by providing real-time feedback about hand movements and forces. This product not only promises to enhance worker safety but also aims to foster a culture of health-consciousness in the workplace.

The Vision Behind the Tactile Sensing Glove

The Tactile Sensing Glove leverages cutting-edge capacitive sensing technology to capture high-resolution, dynamic pressure data that reflects the forces exerted by the hand. Historically, the inability to precisely measure hand force has been a barrier to effectively addressing work-related musculoskeletal disorders (WMSDs), which affect over 50% of workers across various industries. By employing this sophisticated tool, ergonomics engineers can design better tools and workplace layouts while safety regulators can establish clear limits for acceptable hand forces, ultimately enhancing workplace standards.

From Concept to Reality: Key Engineering Lessons

The journey to creating a dependable tactile sensing glove has not been without its challenges. Review of the TactileGlove’s evolution reveals significant engineering insights gained over a decade of development. Five major lessons underscore the significance of internal design, ease of glove removal, and the robustness of materials used:

- Design Flexibility: Early prototypes faced durability issues; however, implementing serpentine wiring eliminated fracture points, showcasing how thoughtful design can enhance flexibility and longevity.

- The Importance of Durability: Recognizing the stress related to removing the glove led to the introduction of reinforced designs, ensuring reliable long-term usage.

- Robustness is Key: Continuous improvements led to significant advancements in durability, ensuring that the TactileGlove withstands not just typical use but heavy-duty demands.

- Custom Fit Matters: The outer glove’s design, including the choice of materials, affects comfort, usability, and overall performance. Improvements here can enhance user experience.

- Connectivity As a Cornerstone: Adapting the glove's connectivity features from Bluetooth Low Energy to Bluetooth 5 allowed for longer ranges with minimal interference, a vital improvement for field use.

Understanding Workplace Ergonomics

Musculoskeletal disorders, primarily linked to workstation ergonomics, can lead to significant healthcare costs and lost productivity. As more businesses implement ergonomic programs, the glove’s capacity to quantify hand stress through precise data will allow for better-designed tools and workstations that aim to prevent MSDs. Implementing such solutions addresses both moral and financial imperatives for business owners and facility managers looking to optimize their operations.

Looking Ahead: The Future of Tactile Sensing Technology

As we look to the future, the Tactile Sensing Glove represents not just a technological advancement but a potential revolution in ergonomics. By equipping workers with data that can dramatically reduce strain and improve task performance, we anticipate a rise in adoption across healthcare, manufacturing, and other sectors. Companies could see a substantial return on investment as they prioritize worker health.

Add Row

Add Row  Add

Add

Write A Comment